Aluminum Processing Team

Can be manufactured around

the clock, 7 days a week.

Can be manufactured around

the clock, 7 days a week.

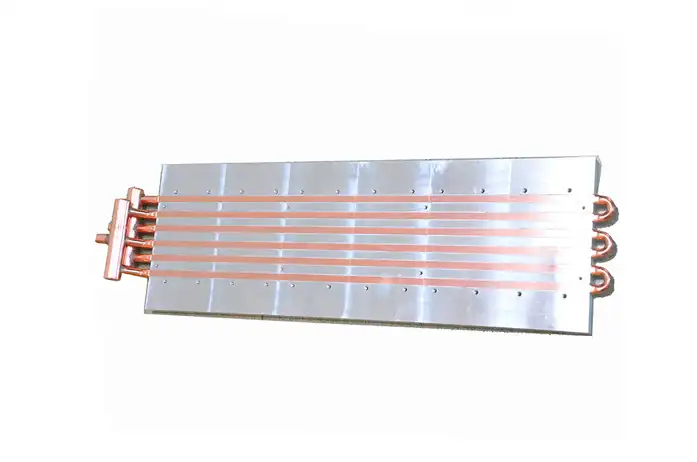

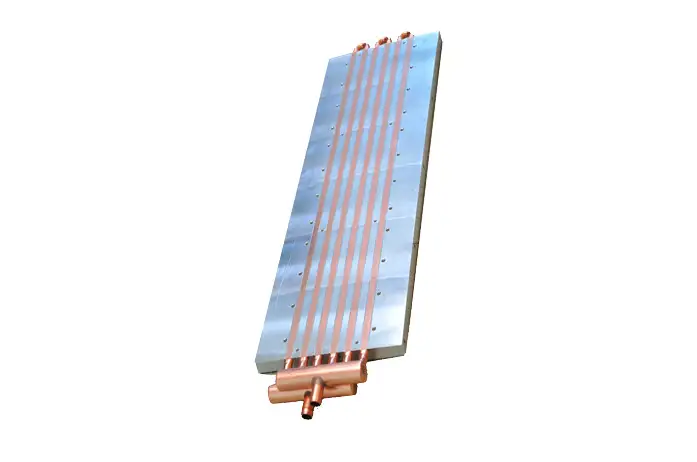

Product Type

Copper Tubed Cold Plate

Overall Dimensions

Typical Total Height: 15-25 mm.

Custom: L 50-1500 mm, W 50-800 mm.

Materials

Base Plate: AL 6061-T6 / AL 6063-T5

Copper Tube: C1220 Oxygen-Free Copper

Port/Connector Options

Threaded, Quick-Disconnect, Barbed (Optional)

Mounting Holes

According to customer drawing/specification

Thermal Performance

Thermal Resistance (R): 0.03 - 0.06 °C/W (@4L/min, 25°C)

Heat Dissipation (Rated): Typ. 500 - 2000 W

Surface Temp. Uniformity (ΔT): < 2 °C

Operating Flow Rate Range

2 - 10 L/min

Pressure Drop (ΔP)

< 35 kPa (@ 4 L/min)

Recommended Coolant

Deionized Water, ≤50% Glycol-Water

1. Thermal-Driven Design

Core Principle: All designs must originate from an accurate heat source layout diagram (locations, dimensions, power levels).

Key Consideration: Providing only total power dissipation is insufficient—this prevents optimization of temperature uniformity and flow path design.

2. Process-Selection Alignment

Core Principle: Match the process to the application: Fly-Cut Surface (for ultimate performance), Deep Tubes (for high pressure/reliability), double side tube (for cost efficiency & dual-side cooling).

Key Consideration: Incorrect selection can lead to significant cost escalation or critical reliability failures.

3. Balanced Flow Path Design

Core Principle: Achieve an optimal balance among flow path length (heat exchange), pressure drop (pumping power), and temperature uniformity.

Key Consideration: Longer flow paths are not inherently better—they cause a sharp increase in pressure drop. Multi-path designs require careful flow distribution.

4. Interface & Integration Priority

Core Principle: Ensure mounting surface flatness ≤ 0.1mm and roughness Ra ≤ 1.6μm.

Key Consideration: This is the prerequisite for achieving low contact thermal resistance. Superior internal performance is negated by poor interface quality. Thermal resistance must be validated under system operating conditions.