Communication and sharing promote growth

Joining Hands for Development!

For heat sink manufacturing, material selection and skiving fin accuracy are the key to success. Faced with the stringent requirements of ultra-thin fin and high-density fin, the core challenge is: how to balance material thermal conductivity, cost and processability? How to break through the equipment limit, achieve micron-level stable accuracy, and ensure tooth shape consistency and heat dissipation efficiency? This directly determines product performance, cost competitiveness and mass production yield.

1-Core issues and challenges of the process

a. Process essence: Layered scraping (rough → fine machining) forms high-density fin pieces

Layered scraping quickly removes excess through rough machining and ensures fin shape accuracy through fine machining, but faces three major contradictions:

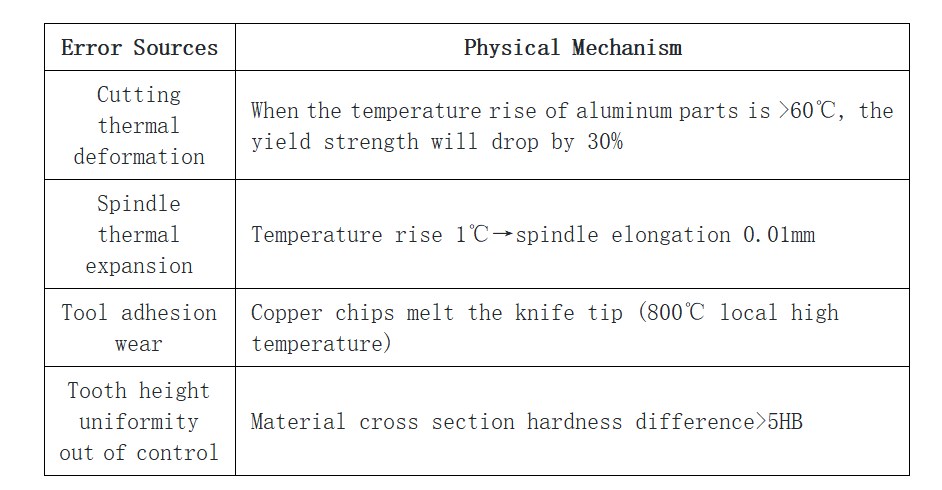

· Thermal deformation control: The high cutting heat generated by rough machining causes local expansion of thin-walled fin pieces. The deformation needs to be compensated during fine machining, otherwise ellipticity errors (such as uneven spacing of heat dissipating fins) will occur.

· Stress balance: The accumulation of residual stress in layered machining causes warping of tooth pieces, especially aluminum (high thermal conductivity but low yield strength), which needs to reduce cutting force through the "small cutting depth and fast feed" strategy.

· Precision transfer: The jagged residual material left over from rough machining increases the load on the fine machining tool, which is easy to cause chatter and lead to fin thickness tolerance.

b. Two major pain points

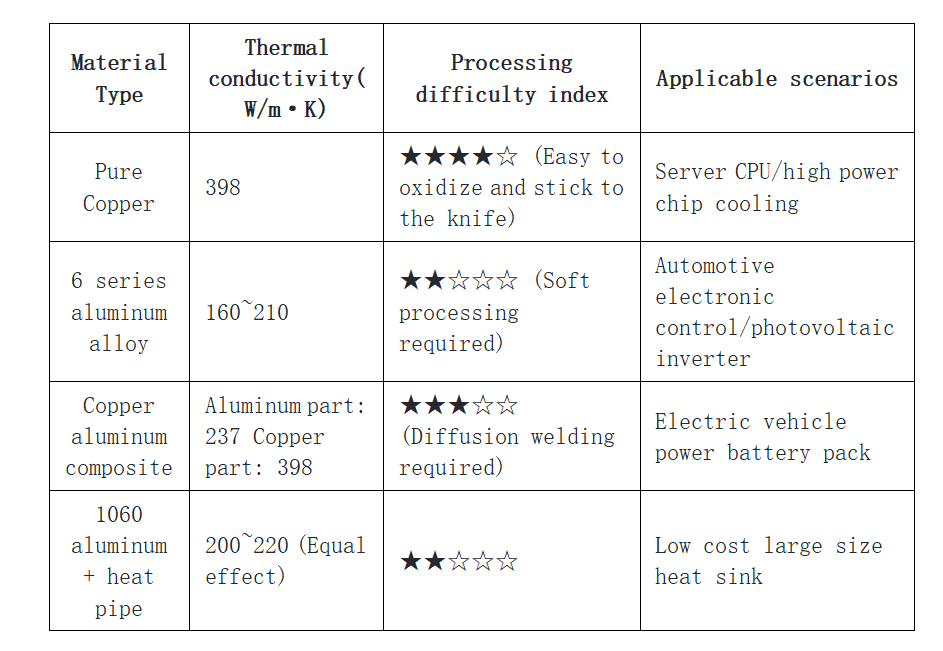

· Heatsink material selection: Heatsink material selection needs to balance thermal conductivity, processability and cost. Through performance comparison and selection decision-making, combined with material modification and cost control, synergistic optimization can be achieved.

Table 1: Quantitative comparison of material properties and selection logic

· Equipment accuracy: Equipment accuracy optimization improves machining accuracy and tool life by suppressing cutting thermal deformation, tool wear and error, using innovative tools and thermal-mechanical coupling error compensation.

Table 2: Causal chain of precision defects

2-Material selection: the key to performance and cost

a. Thermal conductivity demand dominates

· High heat flux scenario (>100W/cm²): Copper (thermal conductivity 380W/m·K) is preferred, and its heat carrying capacity is 30% higher than that of aluminum.

Risk control: Pickling to remove the oxide layer (10% HNO₃) + benzotriazole oil film to prevent secondary oxidation, reducing tool wear by 40%.

Medium and low heat flux scenario (<80W/cm²): Pure aluminum is preferred (thermal conductivity 210W/m·K), which meets most consumer electronics needs and costs only 30% of copper.

b. Cost constraint optimization

· Cost-sensitive projects, material thinning (e.g., aluminum substrate from 4mm→2mm); waste recycling (copper chip recovery rate>95%); local composite design (copper is used only in the heat source contact area).

· Alternative solution, pure aluminum + heat pipe design, equivalent thermal conductivity 200–220W/m·K.

c. Compromise of processing difficulty

· For high fin requirements (>70mm), choose pure aluminum, the fin height limit is 120mm, and the bending resistance is stronger than copper; pretreatment, pre-annealing of aluminum (reducing residual stress) to reduce hardness fluctuations.

· For high-precision fin shape (fin thickness <0.5mm), choose 6 series aluminum, AL6063 is hardened after soft processing, and the fin thickness can be controlled to 0.25mm; Taboo, avoid direct processing of hard copper materials (easy to collapse teeth), low-temperature pretreatment is required.

3- Equipment precision optimization: the core of improving yield rate

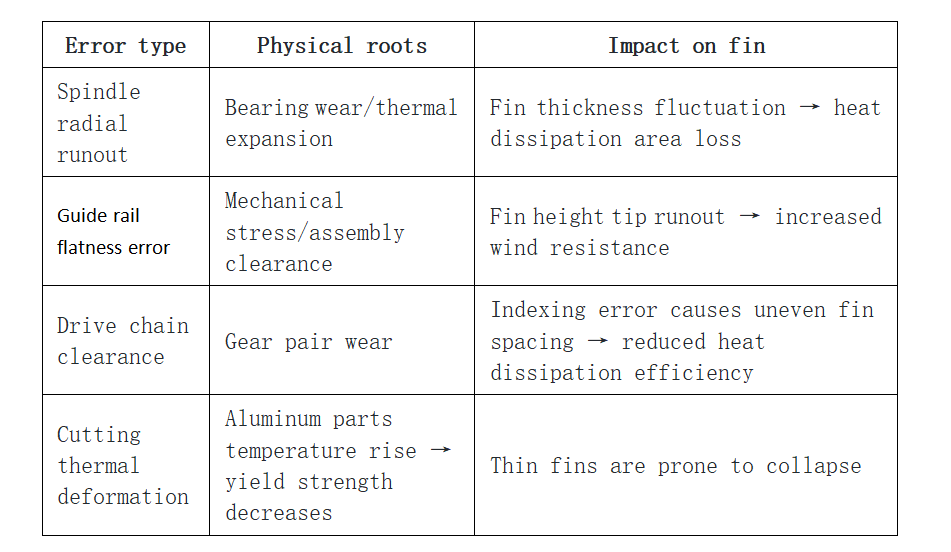

Equipment precision is the core of the skiving process to achieve high-density fins and control deformation and wear.

Table 3: Impact mechanism of equipment error sources on yield

Ideas for optimizing the precision of skiving equipment:

· Core precision improvement: CNC substitution, replacing mechanical transmission with CNC system to eliminate indexing error; thermal deformation suppression, using cold air cutting technology and combining compensation technology to actively control thermal deformation during processing; tool strengthening, applying CBN coating and optimizing geometric structure to improve tool anti-chipping ability.

· Key achievements: Equipment processing accuracy reaches ±0.003mm (micrometer level); successfully supports the design of extreme fins with a thickness of 0.3mm and a fin height of 120mm; production yield has achieved a significant leap from 65% to 95%.

In summary, precise material matching and extreme skiving accuracy are the core barriers of radiator manufacturing. Optimized materials guarantee the foundation of performance, while micron-level precision equipment (CNC transmission, thermal deformation suppression, and durable tools) is the only way to achieve high yield and support extreme fin shape design. Only by continuously optimizing these two cores and proactively deploying advanced precision control technologies can we consolidate the market leading position of radiator processing.

We will regularly update you on technologies and information related to thermal design and lightweighting, sharing them for your reference. Thank you for your attention to Walmate.